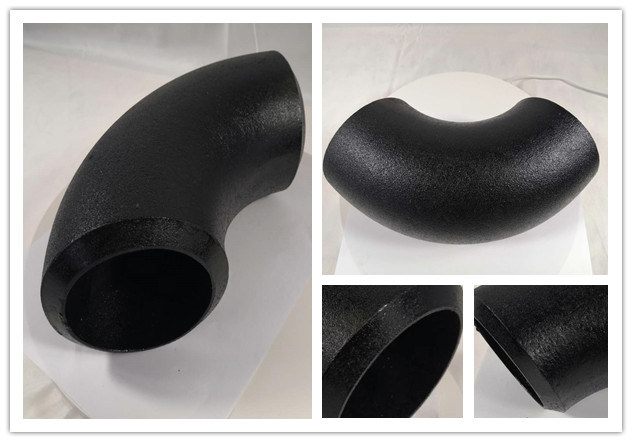

SIFFOFIN SAMFURI

| Sunan Samfuri | Gilashin bututu |

| Girman | 1/2"-36" gwiwar hannu mara sumul (SMLS elbow), 26"-110" an haɗa shi da dinki. Mafi girman diamita na waje zai iya zama 4000mm |

| Daidaitacce | ANSI B16.9, EN10253-2, DIN2605, GOST17375-2001, JIS B2313, MSS SP 75, da sauransu. |

| Kauri a bango | STD, XS, XXS, SCH20, SCH30, SCH40, SCH60, SCH80, SCH160, XXS da sauransu. |

| Digiri | 30° 45° 60° 90° 180°, da sauransu |

| Radius | LR/tsawon radius/R=1.5D,SR/Gajeren radius/R=1D |

| Ƙarshe | Ƙarshen Bevel/BE/buttweld |

| saman | launin yanayi, fenti mai fenti, fenti baƙi, man hana tsatsa da sauransu. |

| Kayan Aiki | Karfe mai ƙarfi:A234WPB, A420 WPL6 St37, St45, E24, A42CP, 16Mn, Q345, P245GH, P235GH, P265GH, P280GH, P295GH, P355GH da sauransu. |

| Karfe mai bututun:ASTM 860 WPHY42, WPHY52, WPHY60, WPHY65, WPHY70, WPHY80 da sauransu. | |

| Karfe mai ƙarfe na Cr-Mo:A234 WP11, WP22, WP5, WP9, WP91, 10CrMo9-10, 16Mo3, 12crmov, da sauransu. | |

| Aikace-aikace | Masana'antar mai; masana'antar jiragen sama da sararin samaniya; masana'antar magunguna, hayakin iskar gas; tashar wutar lantarki; gina jiragen ruwa; sarrafa ruwa, da sauransu. |

| Fa'idodi | kayan da aka shirya, lokacin isarwa da sauri; akwai a cikin kowane girma dabam, an keɓance shi; inganci mai girma |

Kayan Bututu

Kayan aikin bututun da aka haɗa da bututun ƙarfe, tef ɗin bututun ƙarfe, bututun ƙarfe, murfin bututun ƙarfe. Duk waɗannan kayan aikin bututun walda na butt, za mu iya samarwa tare, muna da ƙarin gogewa na shekaru 20 na samarwa.

Idan kuna sha'awar wasu kayan haɗi, da fatan za ku danna LINK ɗin da ke ƙasa don duba cikakkun bayanai.

T-shirt ɗin bututu MAI RAGE BUTUTU Murfin Bututu BUTU MAI LAUNI Kayan Aiki Na Ƙirƙira

GIDAN GWIWA MAI WALDA DA BUTUTU

Elƙwalwar bututun ƙarfe muhimmin sashi ne a cikin tsarin bututu don canza alkiblar kwararar ruwa. Ana amfani da shi don haɗa bututu biyu masu diamita iri ɗaya ko daban-daban, da kuma sa bututun ya juya zuwa wani alkibla na digiri 45 ko digiri 90.

Ga gwiwar hannu na bututun masana'antu, nau'in ƙarshen haɗin shine weld na butt, bisa ga ANSI B16.25. Ana iya bayyana weld na butt, buttweld, da bevel end.

NAURIN GWIWA

Elbow zai iya kasancewa daga kusurwar alkibla, nau'in haɗi, tsayi da radius, da nau'ikan kayan aiki.

An rarraba ta hanyar kusurwar jagora

Kamar yadda muka sani, bisa ga alkiblar ruwa na bututun, ana iya raba gwiwar hannu zuwa matakai daban-daban, kamar digiri 45, digiri 90, digiri 180, waɗanda sune digiri mafi yawan gama gari. Haka kuma akwai digiri 60 da digiri 120, ga wasu bututun na musamman.

Ga gwiwar hannu mai digiri 90, an kuma bayyana gwiwar hannu mai digiri 90, ko gwiwar hannu mai digiri 90.

Menene Radius na Elbow

Ma'anar radius ɗin gwiwar hannu shine radius mai lanƙwasa. Idan radius ɗin yayi daidai da diamita na bututu, ana kiransa gajeriyar radius elbow, wanda kuma ake kira SR elbow, yawanci don bututun mai ƙarancin matsi da ƙarancin gudu.

Idan radius ɗin ya fi diamita na bututu girma, R ≥ 1.5 Diamita, to muna kiransa dogon radius ignel (LR Elbow), wanda ake amfani da shi don bututun mai matsin lamba mai yawa da kuma yawan kwarara.

Idan radius ya fi 1.5D, koyaushe ana kiransa lanƙwasa. Kayan aikin bututun lanƙwasa gwiwar hannu. Kamar gwiwar hannu ta 2d, lanƙwasa ta 2d, gwiwar hannu ta 3d, lanƙwasa ta 3d, da sauransu.

Rarrabawa ta Kayan Aiki

Karfe mai sauƙin amfani, wanda kuma ake kira da ƙarfe mai laushi ko baƙin ƙarfe. Kamar ASTM A234 WPB

Idan kana neman gwiwar hannu na bakin karfe, danna wannan hanyar haɗin yanar gizo don ƙarin bayani:Gwiwar Bakin Karfe

Nau'in Siffa

Zai iya zama daidai gwargwado ko Rage gwiwar hannu

GINGWU

Fashewar Yashi

Bayan an yi zafi, muna shirya fashewar yashi don ya zama mai tsabta da santsi.

Bayan fashewar yashi, don guje wa tsatsa, ya kamata a yi fenti baƙi ko man hana tsatsa, mai mai zafi (HDG), epoxy, 3PE, saman da ya ɓace, da sauransu. Wannan ya dogara ne akan buƙatar abokin ciniki.

MAGANIN ZAFI

1. A ajiye samfurin kayan da aka samo don a bi diddiginsu.

2. Shirya maganin zafi kamar yadda aka tsara.

ALAMA

Ana iya yin alama iri-iri, ana iya lanƙwasawa, fenti, ko kuma a iya yin rubutu a kan takarda. Ko kuma bisa buƙatarku. Mun yarda mu yi alama a kan tambarin ku.

CIKAKKEN HOTUNA

1. Ƙarshen bevel kamar yadda ANSI B16.25 ya tanada.

2. A fara busar da yashi, sannan a yi fenti mai kyau. Haka kuma ana iya shafa masa fenti.

3. Ba tare da lamination da fasa ba.

4. Ba tare da wani gyaran walda ba.

DUBAWA

1. Ma'aunin girma, duk a cikin haƙurin da aka saba.

2. Juriyar kauri: +/-12.5%, ko kuma bisa buƙatarka

3. PMI

4. Gwajin MT, UT, da X-ray

5. Karɓi dubawa na ɓangare na uku

6. Takardar shaidar samar da kayayyaki ta MTC, takardar shaidar EN10204 3.1/3.2

MAKUNGUNAN & JIRGIN SAUYA

1. An lulluɓe shi da akwatin plywood ko pallet ɗin plywood kamar yadda ISPM15 ta tanada

2. Za mu sanya jerin kayan tattarawa a kan kowace fakiti

3. Za mu sanya alamun jigilar kaya a kan kowace fakiti. Kalmomin alamun suna kan buƙatarku.

4. Duk kayan fakitin itace ba su da hayaki mai gurbata muhalli

Tambayoyin da ake yawan yi akai-akai

1. Menene ANSI B16.9?

ANSI B16.9 yana nufin ma'aunin Cibiyar Matsayin Ƙasa ta Amurka (ANSI) don kayan haɗin bututun butt-weld da aka yi a masana'anta. Yana ƙayyade girma, juriya, kayan aiki da buƙatun gwaji don kayan haɗin bututun butt welded.

2. Menene kayan haɗin bututun da aka haɗa da butt welded?

Kayan haɗin weld na butt sune kayan haɗin bututu waɗanda ake haɗa su a ƙarshen bututu ko wasu kayan haɗin don samar da haɗin gwiwa mai ƙarfi wanda ba ya zubewa. Ana haɗa weld na butt ta hanyar saka ƙarshen bututu ko haɗawa a cikin soket na wani bututu ko haɗawa da walda haɗin.

3. Menene gwiwar hannu ta walda ta carbon mai digiri 180?

Gilashin ƙarfe mai walda mai digiri 180 wani bututu ne da ake amfani da shi don canza alkiblar bututun digiri 180. Ana samunsa a cikin ƙirar radius mai tsayi ko gajere kuma an yi shi da kayan ƙarfe na carbon. Yi amfani da haɗin walda mai butt don haɗa gwiwar hannu da bututu ko wani kayan da aka haɗa.

4. Menene buƙatun gwiwar hannu da aka haɗa a cikin ANSI B16.9?

ANSI B16.9 ya ƙayyade girma, juriya, kayan aiki, da buƙatun gwaji don gwiwar hannu da aka haɗa. Yana ba da jagora kan tsarin kera, gami da diamita na waje, kauri bango, girma daga tsakiya zuwa ƙarshe da radius na lanƙwasa ga gwiwar hannu daban-daban.

5. Menene fa'idodin amfani da ƙarfen carbon don kayan haɗin bututun da aka haɗa da butt?

Ana amfani da ƙarfen carbon sosai a cikin bututun da aka haɗa da butt welded saboda ƙarfinsa mai kyau, juriyarsa da juriyar tsatsa. Yana iya jure matsin lamba mai yawa da yanayin zafi mai yawa kuma yana da aiki mai tsada. Kayan aikin ƙarfen carbon sun dace da aikace-aikace iri-iri a masana'antar mai da iskar gas, sinadarai na petrochemical da wutar lantarki.

6. Za a iya amfani da gwiwar hannu na ƙarfe mai digiri 180 a cikin tsarin matsin lamba mai ƙarfi da kuma tsarin ƙarancin matsin lamba?

Eh, ana iya amfani da gwiwar hannu mai walda na ƙarfe mai digiri 180 a cikin tsarin matsi mai girma da ƙasa. Duk da haka, ya kamata a yi la'akari da takamaiman ƙimar matsi na gwiwar hannu bisa ga buƙatun aikace-aikacen. Dole ne a tabbatar da kayan haɗi don dacewa da matsin lambar tsarin da ake tsammani.

7. Shin gwiwar hannu mai walda mai digiri 180 ya dace da yanayin lalata?

Eh, kayan haɗin ƙarfe na carbon gabaɗaya sun dace da amfani a cikin muhallin da ke lalata abubuwa. Duk da haka, ya kamata a yi la'akari da nau'in da yawan kayan lalata abubuwa yayin zaɓar kayan aiki. A cikin muhallin da ke ƙara lalata abubuwa, ana iya buƙatar ƙarin kariyar tsatsa, kamar su rufin waje ko rufin da aka yi da itace.

8. Za a iya amfani da gwiwar hannu na ƙarfe mai digiri 180 tare da bututun da aka yi da wasu kayan aiki?

Eh, ana iya amfani da gwiwar hannu na ƙarfe mai nauyin digiri 180 da bututun da aka yi da bakin ƙarfe, ƙarfe mai ƙarfe, ƙarfe marasa ƙarfe da sauran kayayyaki. Duk da haka, don aiki na dogon lokaci, ya kamata a yi la'akari da jituwa tsakanin kayan aiki da yuwuwar tasirin lalata galvanic.

9. Waɗanne gwaje-gwaje aka yi a kan gwiwar hannu na ANSI B16.9 na ƙarfe mai digiri 180?

ANSI B16.9 ya ƙayyade gwaje-gwaje daban-daban don tabbatar da inganci da amincin gwiwar ƙarfe mai walda mai digiri 180. Waɗannan gwaje-gwajen na iya haɗawa da duba girma, duba gani, duba ultrasonic, gwajin ƙarfin tensile, gwajin tasiri da gwajin da ba ya lalatawa (kamar shigar fenti ko duba hoto).

10. Za a iya gyara ko haɗa gwiwar ƙarfen carbon mai digiri 180 a wurin aiki?

Ana iya gyara ko walda gwiwar ƙarfe mai digiri 180 a fagen aiki amma ya kamata ma'aikata masu ƙwarewa da ƙwarewa su yi shi bisa ga ƙa'idodi da tsare-tsare na masana'antu. Ana ba da shawarar a tuntuɓi masana'anta ko ƙwararren injiniya don neman jagora don tabbatar da aminci da aikin kayan haɗi da aka gyara.

Kayan aikin bututun ruwa sune muhimman abubuwa a tsarin bututun, ana amfani da su don haɗawa, sake tura su, karkatar da su, canza girmansu, rufewa ko sarrafa kwararar ruwa. Ana amfani da su sosai a fannoni kamar gini, masana'antu, makamashi da ayyukan birni.

Muhimman Ayyuka:Yana iya yin ayyuka kamar haɗa bututu, canza alkiblar kwarara, rabawa da haɗa kwarara, daidaita diamita na bututu, rufe bututu, sarrafawa da daidaitawa.

Tsarin Aikace-aikace:

- Gina ruwa da magudanar ruwa:Ana amfani da gwiwar hannu na PVC da kuma PPR tris don hanyoyin sadarwa na bututun ruwa.

- Bututun masana'antu:Ana amfani da flanges na bakin karfe da gwiwar hannu na ƙarfe mai ƙarfe don jigilar kayan haɗin sinadarai.

- Sufurin makamashi:Ana amfani da bututun ƙarfe mai ƙarfi a bututun mai da iskar gas.

- HVAC (Dumamawa, Samun Iska, da Kwandishan):Ana amfani da kayan haɗin bututun tagulla don haɗa bututun firiji, kuma ana amfani da haɗin gwiwa masu sassauƙa don rage girgiza.

- Ban ruwa na noma:Masu haɗin sauri suna sauƙaƙa haɗawa da wargaza tsarin ban ruwa na feshin ruwa.

-

90 digiri gwiwar hannu Tee reducer carbon karfe Butt w ...

-

ƙarfe mai ƙarfe sch80 butt welded end 12 inch sch4...

-

Asme b16.9 jadawalin 80 bututun ƙarfe kayan aiki Tee ...

-

na'urar rage yawan carbon astm a105 Black...

-

ANSI B16.9 Carbon Karfe Mai Digiri 45 Na Walda

-

Bakin ƙarfe mai tsayi bend1d 1.5d 3d radius 5d 3...