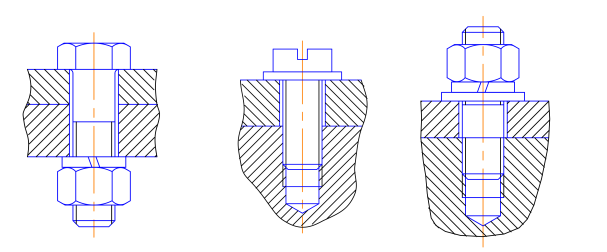

Nau'in ƙulli daban-daban

Bambancin da ke tsakanin ƙusoshi da sukurori yana cikin ɓangarori biyu: ɗaya shine siffar, ɓangaren ƙusoshin ƙusoshin yana da matuƙar muhimmanci ya zama silinda, ana amfani da shi don shigar da goro, amma ɓangaren ƙusoshin ƙusoshin wani lokacin yana da siffar mazugi ko ma da tip; ɗayan kuma shine Ta amfani da aikin, ana ƙusoshin ƙusoshin cikin kayan da aka nufa maimakon goro. A lokuta da yawa, ƙusoshin kuma suna aiki daban-daban, kuma ana ƙusoshin kai tsaye cikin ramin zare da aka riga aka haƙa, ba tare da buƙatar goro ta yi aiki tare da shi ba. A wannan lokacin, ana rarraba ƙusoshin a matsayin sukurori dangane da aiki.

Siffa da manufar kan ƙugiya an raba su zuwa ƙugiya mai siffar murabba'i, ƙugiya mai siffar murabba'i, ƙugiya mai zagaye mai zagaye, ƙugiya mai ramuka, ƙugiya mai ramuka, ƙugiya mai siffar T, ƙugiya mai siffar ƙugiya (tushe) da sauransu.

Zaren ginshiƙin za a iya raba shi zuwa zare mai kauri, zare mai kyau da zaren inci, don haka ana kiransa ƙulli mai kyau da ƙulli mai inci.

Tsarin Samarwa

Da farko, naushin farko yana motsawa don shirya wayar don yin ƙusa, sannan naushin na biyu yana motsawa don sake ƙera wayar da kuma siffanta samfurin da aka gama. A cikin tsarin sanyi, naushin da aka gyara (naushin matsewa) da kuma naushin buga (ƙusa)

Adadin kawunan ba iri ɗaya ba ne. Wasu sukurori masu rikitarwa na iya buƙatar naushi da yawa don haɗuwa tare, wanda ke buƙatar kayan aiki masu tashoshi da yawa don yin sukurori. Bayan motsi na naushi, an kammala kan sukurori, amma ba a zare ɓangaren shaft ɗin sukurori ba. Hanyar samar da zaren sukurori ita ce birgima zaren. Mirgina zaren ita ce amfani da mayukan birgima guda biyu masu juyawa (faranti masu gogewa) tare da haƙoran zare don matse wani abu mai silinda wanda injin mai tashoshi da yawa ko injin kai ya samar a tsakiya.

Bayan an yi amfani da shi wajen shafa haƙoran, an samar da dukkan sukurin. Tabbas, domin a sa sukurin ya yi haske da kyau, yawanci ana yin aikin gyaran saman. Kamar tsaftacewa da kuma cire sukurin bakin karfe, amfani da wutar lantarki a saman sukurin karfen carbon, da sauransu. An yi su da launuka daban-daban na manne sukurin.

Kayan aikin bututun ruwa sune muhimman abubuwa a tsarin bututun, ana amfani da su don haɗawa, sake tura su, karkatar da su, canza girmansu, rufewa ko sarrafa kwararar ruwa. Ana amfani da su sosai a fannoni kamar gini, masana'antu, makamashi da ayyukan birni.

Muhimman Ayyuka:Yana iya yin ayyuka kamar haɗa bututu, canza alkiblar kwarara, rabawa da haɗa kwarara, daidaita diamita na bututu, rufe bututu, sarrafawa da daidaitawa.

Tsarin Aikace-aikace:

- Gina ruwa da magudanar ruwa:Ana amfani da gwiwar hannu na PVC da kuma PPR tris don hanyoyin sadarwa na bututun ruwa.

- Bututun masana'antu:Ana amfani da flanges na bakin karfe da gwiwar hannu na ƙarfe mai ƙarfe don jigilar kayan haɗin sinadarai.

- Sufurin makamashi:Ana amfani da bututun ƙarfe mai ƙarfi a bututun mai da iskar gas.

- HVAC (Dumamawa, Samun Iska, da Kwandishan):Ana amfani da kayan haɗin bututun tagulla don haɗa bututun firiji, kuma ana amfani da haɗin gwiwa masu sassauƙa don rage girgiza.

- Ban ruwa na noma:Masu haɗin sauri suna sauƙaƙa haɗawa da wargaza tsarin ban ruwa na feshin ruwa.