Flange na Orifice WN 4″ 900# RF A105

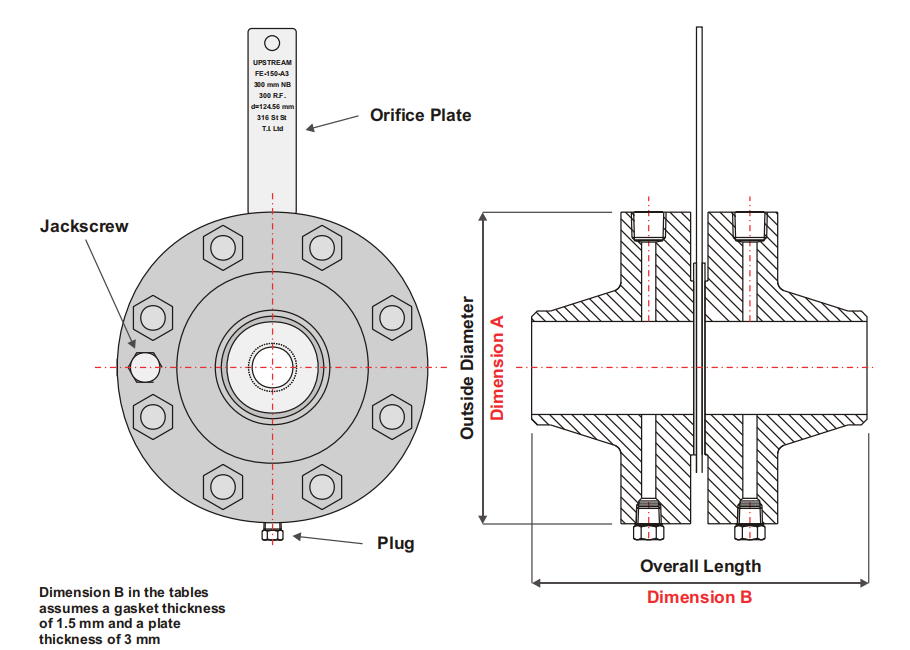

Flange mai tsawon inci 4 da digo 900# na Weld Neck Orifice Flange a cikin ASTM A105 yana wakiltar wani ɓangaren auna kwararar ruwa mai inganci wanda aka ƙera don mahimman ayyukan matsi mai ƙarfi a masana'antar mai da iskar gas, man fetur, da samar da wutar lantarki. An ƙera shi bisa ƙa'idodin ASME B16.36 (Orifice Flanges) da B16.5, wannan flange ya haɗa da ramukan magudanar ruwa guda biyu na Grade 3 a matsayin daidaitattun, yana sauƙaƙa matsi mai daidaitacce da kuma tabbatar da ingantaccen ma'aunin matsin lamba don canja wurin riƙewa da sarrafa tsari.

BAYANI

| Sunan Samfuri | wuyan walda Orifice flange | |||

| GIRMA | 1" sama da 24" | |||

| Matsi | 150#-2500# | |||

| Daidaitacce | ANSI B16.36 | |||

| Kauri a bango | SCH5S, SCH10S, SCH10, SCH40S, STD, XS, XXS, SCH20, SCH30, SCH40, SCH60, SCH80, SCH160, XXS da dai sauransu. | |||

| Kayan Aiki | Bakin ƙarfe: A182F304/304L, A182 F316/316L, A182F321, A182F310S, A182F347H, A182F316Ti, A403 WP317, 904L, 1.4301,1.4307,1.4401,1.4571,1.4541, 254Mo da sauransu. Karfe mai amfani da carbon: A105, A350LF2, Q235, St37, St45.8, A42CP, E24, A515 Gr60, A515 Gr 70 | |||

| Bakin ƙarfe mai duplex: UNS31803, SAF2205, UNS32205, UNS31500, UNS32750, UNS32760, 1.4462,1.4410,1.4501 da sauransu. Karfe mai bututun: A694 F42, A694F52, A694 F60, A694 F65, A694 F70, A694 F80 da sauransu. | ||||

| Haɗin nickel: inconel600, inconel625, inconel690, incoloy800, incoloy 825, incoloy 800H, C22, C-276, Monel400, Alloy20 da sauransu. Haɗin Cr-Mo: A182F11, A182F5, A182F22, A182F91, A182F9, 16mo3 da sauransu. | ||||

| Aikace-aikace | Masana'antar mai; masana'antar noma da sararin samaniya; masana'antar magunguna; shaƙar iskar gas; tashar wutar lantarki; gina jiragen ruwa; sarrafa ruwa, da sauransu. | |||

| Fa'idodi | kayan da aka shirya, lokacin isarwa da sauri; akwai a cikin kowane girma dabam, an keɓance shi; inganci mai girma | |||

An ƙera shi daga ƙarfen carbon na ASTM A105—wanda aka tabbatar da ingancin bin diddiginsa sau biyu—wannan flange ɗin wuyan walda yana ba da ƙarfin injina da juriyar tasiri. Matsayin matsin lamba na 900# yana tabbatar da inganci a cikin tsarin da ke aiki har zuwa 1500 psi a 100°F (tare da daidaita zafin jiki mai dacewa). Tsarinsa yana ba da fifiko ga sauyawa mai santsi daga bututu zuwa flange ta wuyan haɗin gwiwa, yana rage hayaniya da inganta yanayin kwararar ruwa a sama da ƙasan farantin saman.

MATAKAN GIRMA

NUNA BAYANIN KAYAN AIKI

Gine-gine na ƙirƙira:

Kowace flange tana farawa ne a matsayin billet mai zafi na ƙarfe mai carbon, wanda aka ƙera a ƙarƙashin matsin lamba mai yawa don inganta tsarin hatsi, haɓaka halayen injiniya (musamman tauri da juriya ga gajiya), da kuma kawar da gurɓatattun abubuwa ko lahani na ciki. Wannan tsari yana tabbatar da daidaito da ƙarfi fiye da madadin siminti ko faranti.

Daidaita Injin:

Injin CNC yana tabbatar da cewa yana da juriya ga dukkan muhimman wurare. An yi amfani da injin don yin amfani da bututun don rage matsalar kwararar ruwa. Fuskar da aka ɗaga ta yi daidai (125-250 AARH finish) don haɓaka riƙon gasket da ingancin rufewa. Ana haƙa ramukan bolt kuma an yi musu fuska tabo don tabbatar da daidaito da kuma ɗaukar bolt daidai.

Siffofi na Musamman na Orifice:

Flange ɗin ya ƙunshi ramuka biyu na famfo na NPT 1/2" (ko makamancin haka) na aji 3, waɗanda aka sanya su a wurare daban-daban a digiri 90, waɗanda suka dace da daidaitattun tsarin flange na ofice don haɗin mai watsa matsi. An tsara saman haɗuwa don ɗaukar farantin ofice na yau da kullun tare da rami mai kaifi mai kaifi don auna kwararar daidai.

Shiri na Walda:

An yi wa ƙarshen wuyan walda a kusurwar 37.5° daidai gwargwado tare da ƙasa mai girman 1.6mm, wanda aka shirya don cikakken shiga cikin walda zuwa bututun Schedule 160 da ya dace. Wannan ƙirar tana tabbatar da cewa an cire walda daga fuskar flange mai ƙarfi, wanda ke samar da mafi girman daidaiton haɗin gwiwa.

Takaddun Shaidar Kayan Aiki:

An bayar da cikakken takardar shaida ta ASTM A105 guda biyu (kayan sinadarai da na inji daga binciken zafi da samfura), yana tabbatar da cewa kayan ya cika ko ya wuce ƙayyadadden ƙarfin samarwa (250 MPa) da ƙarfin juriya (485 MPa).

ALAMOMIN DA RUFEWA

Ana shirya kowanne flange na sama daban-daban don jigilar kaya. Bayan an gama shafa man hana tsatsa ko kuma shafa mai na VCI (Vapor Corrosion Inhibitor), flange ɗin zai naɗe da takarda mai ƙarfi ko kuma mai hana ruwa shiga. Ana kare saman da aka yi da injina masu mahimmanci - musamman fuskar da aka ɗaga da kuma bulo - da murfin filastik ko kwali da aka yanke musamman. Sannan a ɗaure flange ɗin da kyau a kan pallet na katako ko a naɗe shi a cikin akwati na katako mai ƙarfi, ya danganta da adadin oda da inda za a je.

DUBAWA

Takaddun Shaidar Kayan Aiki: Kowace flange tana da cikakken Takaddun Shaidar Gwajin Injin (MTC) wanda ya dace da EN 10204 3.1 / ASTM A961. Wannan takardar shaidar tana ba da damar gano ainihin zafin ƙarfe kuma ya haɗa da:

Cikakken nazarin sinadarai (C, Mn, P, S, Si, Cu, da sauransu)

- Sakamakon gwaje-gwajen injiniya (Ƙarfin Tashin Hankali, Ƙarfin Yawa, Tsawaita, Rage Yanki)

- Sakamakon gwajin Charpy Impact (idan an ƙayyade shi don sabis na ƙarancin zafin jiki)

- Bayanan maganin zafi (daidaitawa, idan an yi amfani da shi)

SHARI'AR HAƊIN GWIWA

An ƙera wannan flange don takamaiman aikace-aikacen aunawa, yana ba da tabbacin kwanciyar hankali a ƙarƙashin yanayin zafi da matsin lamba. Kammalawar Raised Face (RF) tana tabbatar da ingantaccen hatimi tare da gaskets na haɗin gwiwa masu karkace ko zobe, yayin da ginin bango mai nauyi na Schedule 160 yana ba da ƙarin gefen aminci don ayyukan rage lalacewa ko raguwar matsin lamba mai yawa. A matsayin ginshiƙi na ma'aunin ruwa mai aminci da daidaito, wannan flange na orifice muhimmin sashi ne ga injiniyoyi waɗanda ke buƙatar daidaito, dorewa, da cikakken bin ƙa'idodin kayan aikin matsin lamba na duniya.

Tsarin Samarwa

| 1Zaɓi ainihin kayan da aka ƙera | 2. Yanke kayan da aka ƙera | 3. Kafin dumamawa |

| 4. Ƙirƙira | 5. Maganin zafi | 6. Injin da ba shi da ƙarfi |

| 7. Hakowa | 8. Kyakkyawan machining | 9. Alamar |

| 10. Dubawa | 11. Shiryawa | 12. Isarwa |

Yanayi Mai Yawa na Aikace-aikace: An ƙera wannan flange na orifice mai inci 4 900 # don aikace-aikace masu wahala a cikin masana'antu da yawa masu mahimmanci:

- Mai da Iskar Gas: Tashoshin aunawa na adana kaya, ma'ajiyar samar da rijiyoyin ruwa, layukan tsotsa/saukewar ruwa a tashar compressor, da layukan sarrafa matatun mai don samfuran danye, iskar gas, ko na'urorin tacewa.

- Man Fetur da Sinadarai: Daidaitaccen sarrafa ciyarwa ga masu samar da wutar lantarki, auna kwararar kwararar ruwa mai ƙarfi ko mai daraja, da tsarin tururi da danshi mai amfani.

- Samar da Wutar Lantarki: Babban layin tururi, ruwan abinci, da iskar gas a cikin tashoshin wutar lantarki na zafi, inda ma'aunin kwararar taro daidai yake da mahimmanci don inganci da aminci.

- Kayayyakin Aiki Masu Matsi Mai Yawa: Duk wani masana'antu da ke buƙatar ingantaccen ma'aunin kwarara mai inganci don sarrafa tsari, lissafi, ko haɗin gwiwa na aminci.

Amfanin Kayayyakin Kamfaninmu:

- Ƙirƙira da Injin Gina Gida: Muna da cikakken iko kan tsarin samarwa—daga kayan da aka ƙera zuwa flange da aka gama—don tabbatar da inganci, bin diddiginsu, da kuma bin tsarin aiki.

- Ƙwarewar Fasaha: Ƙungiyar injiniyanmu za ta iya ba da tallafi kan girman ofice, zaɓin gasket, ƙayyadaddun ƙarfin shigarwa, da kuma bin ƙa'idodin takamaiman aikin (misali, Shell DEPs, ƙa'idodin Aramco).

- Sauƙi & Keɓancewa: Duk da cewa muna samar da flanges na B16.36 na yau da kullun, muna kuma iya ɗaukar buƙatu na musamman, kamar saitunan ramuka daban-daban (famfon kusurwa, famfon radius), rufin musamman, ko maganin zafi don aikace-aikacen ƙarancin zafin jiki.

- Kayan Aiki Masu Kyau: A matsayinmu na masana'anta kai tsaye tare da ƙwarewar fitarwa mai yawa, muna bayar da ingantaccen lokacin jagora da kuma inganta marufi da jigilar kaya don isar da kayayyaki zuwa wuraren aiki a duk duniya cikin farashi mai araha.

- Tabbatar da Inganci: Alƙawarinmu ya wuce isar da kaya. Muna ba da cikakkun takardu da tallafi don tabbatar da cewa flanges ɗinmu suna haɗuwa cikin tsarin bututunku ba tare da wata matsala ba, tare da samar da shekaru na ingantaccen sabis.

Kayan aikin bututun ruwa sune muhimman abubuwa a tsarin bututun, ana amfani da su don haɗawa, sake tura su, karkatar da su, canza girmansu, rufewa ko sarrafa kwararar ruwa. Ana amfani da su sosai a fannoni kamar gini, masana'antu, makamashi da ayyukan birni.

Muhimman Ayyuka:Yana iya yin ayyuka kamar haɗa bututu, canza alkiblar kwarara, rabawa da haɗa kwarara, daidaita diamita na bututu, rufe bututu, sarrafawa da daidaitawa.

Tsarin Aikace-aikace:

- Gina ruwa da magudanar ruwa:Ana amfani da gwiwar hannu na PVC da kuma PPR tris don hanyoyin sadarwa na bututun ruwa.

- Bututun masana'antu:Ana amfani da flanges na bakin karfe da gwiwar hannu na ƙarfe mai ƙarfe don jigilar kayan haɗin sinadarai.

- Sufurin makamashi:Ana amfani da bututun ƙarfe mai ƙarfi a bututun mai da iskar gas.

- HVAC (Dumamawa, Samun Iska, da Kwandishan):Ana amfani da kayan haɗin bututun tagulla don haɗa bututun firiji, kuma ana amfani da haɗin gwiwa masu sassauƙa don rage girgiza.

- Ban ruwa na noma:Masu haɗin sauri suna sauƙaƙa haɗawa da wargaza tsarin ban ruwa na feshin ruwa.

-

AMSE B16.5 A105 ƙera wuyan walda na ƙarfe mai ƙarfe f...

-

ASME B 16.5 CS SA 105N LWNFF 20inci 600LB LWN F...

-

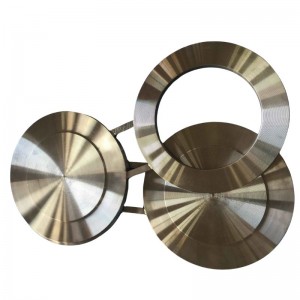

ASME b16.48 Siffar ƙarfe mai kama da carbon 8 ...

-

Na musamman High Quality 304 Bakin Karfe Flanged...

-

Ansi B16.5 A105 Baƙin Carbon Karfe Zamewa akan Flange

-

ANSI B16.5 Ƙirƙirar Bakin Karfe Soket Weld F...