mai ɓoye faifan maɓalli mai faɗi A515 gr, siffa 60 mai siffar 8 mai ban sha'awa

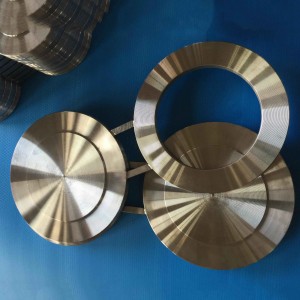

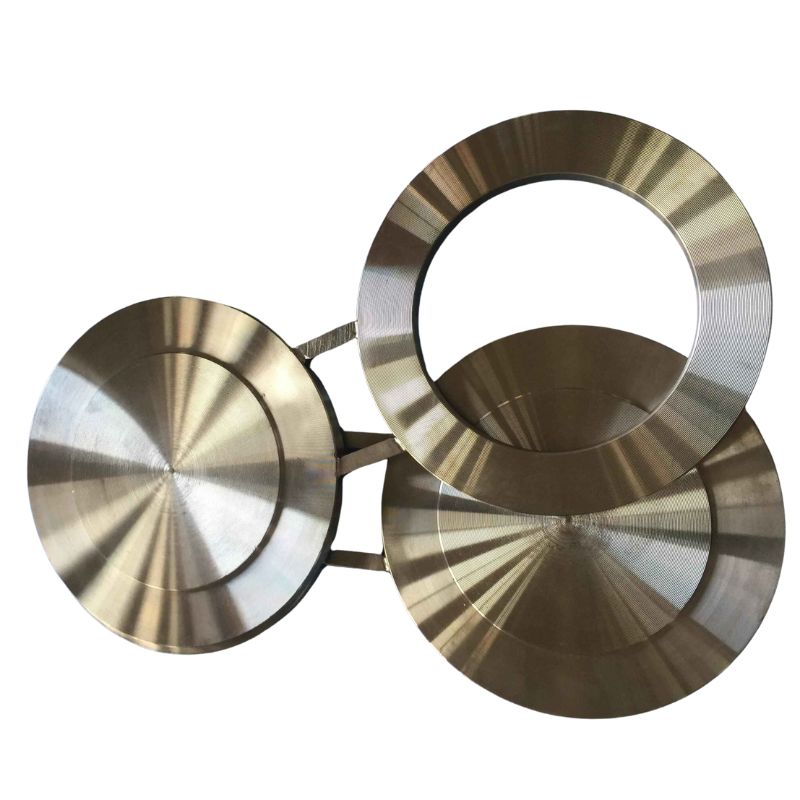

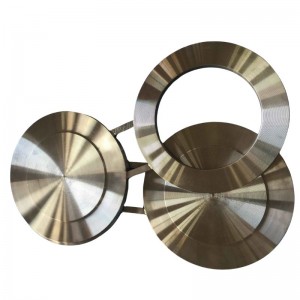

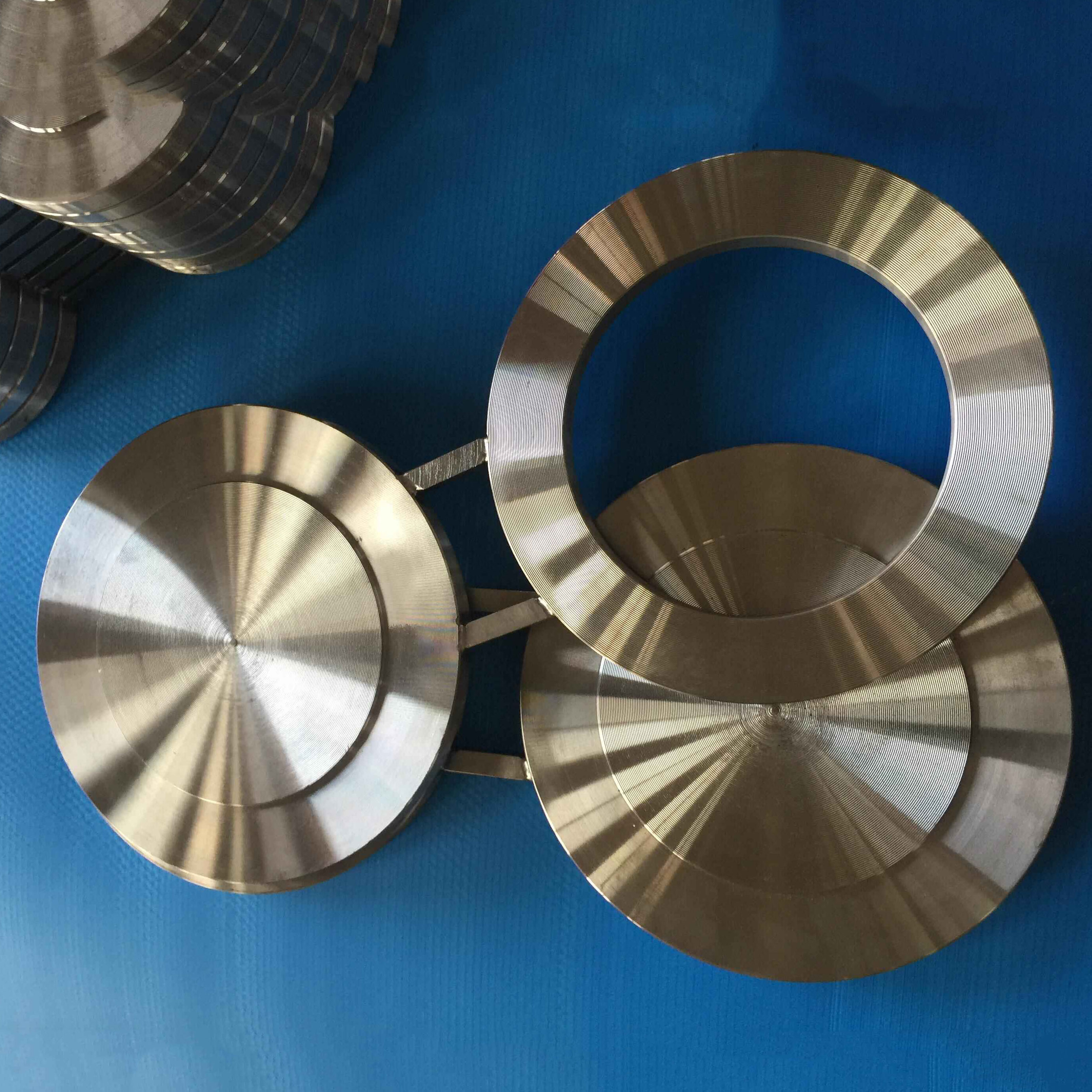

Na'urar Paddle Blank Spacer a cikin ASTM A515 Grade 60, wacce aka tsara a matsayin Flange na Sparkle Blind Flange, na'urar aminci ce mai mahimmanci da keɓewa a cikin tsarin bututun masana'antu. Yana haɗa ayyuka uku cikin dabara zuwa naúrar ƙarfi ɗaya: farantin makafi mai ƙarfi don keɓewa mai kyau, zoben spacer don kwarara, da kuma yanar gizo mai haɗawa tare da maƙallin "paddle" mai faɗi don gane gani bayyananne.

An ƙera ko aka ƙera shi daga ingancin bututun matsi na ASTM A515 Grade 60 carbon steel, wannan ɓangaren yana ba da ƙarfi da juriya mai kyau don matsakaicin zafi zuwa matsakaicin zafi. Tsarin "siffa ta 8" yana bawa masu aiki damar tantance matsayin layin cikin sauri (a buɗe ko a ware) daga nesa, muhimmin fasali ne don hanyoyin kullewa/tagout (LOTO) da amincin masana'anta. An ƙera shi bisa ga ƙa'idodin ASME B16.48, yana tabbatar da ingantaccen aiki azaman layin da babu komai, yana ba da hatimi mai cikakken ƙarfi, wanda ke hana zubewa lokacin da aka ɗaure ƙarshen ƙarfi tsakanin flanges. Tsarinsa mai ƙarfi yana sa ya zama kayan aiki mai mahimmanci don kiyaye lafiya, gwajin tsarin, da canje-canjen tsarin aiki a cikin yanayi masu wahala.

BAYANI

| Sunan Samfuri | Ƙunƙarar makafi |

| Girman | 1/2"-250" |

| Matsi | 150#-2500#,PN0.6-PN400,5K-40K,API 2000-15000 |

| Daidaitacce | ANSI B16.5, EN1092-1, SABA1123, JIS B2220, DIN, GOST, UNI, AS2129, API 6A, da dai sauransu. |

| Kauri a bango | SCH5S, SCH10S, SCH10, SCH40S, STD, XS, XXS, SCH20, SCH30, SCH40, SCH60, SCH80, SCH160, XXS da dai sauransu. |

| Kayan Aiki | Bakin karfe:A182F304/304L, A182 F316/316L, A182F321, A182F310S, A182F347H, A182F316Ti, 317/317L, 904L, 1.4301, 1.4307, 1.4401, 1.4571, 1.4541, 254Mo da sauransu. |

| Karfe mai ƙarfi:A105, A350LF2, S235Jr, S275Jr, St37, St45.8, A42CP, A48CP, E24, A515 Gr60, A515 Gr 70 da sauransu. | |

| Bakin ƙarfe mai duplex: UNS31803, SAF2205, UNS32205, UNS31500, UNS32750, UNS32760, 1.4462, 1.4410, 1.4501 da sauransu. | |

| Karfe mai bututun:A694 F42, A694F52, A694 F60, A694 F65, A694 F70, A694 F80 da sauransu. | |

| Haɗin nickel:inconel600, inconel625, inconel690, incoloy800, incoloy 825, incoloy 800H, C22, C-276, Monel400, Alloy20 da sauransu. | |

| Haɗin Cr-Mo:A182F11, A182F5, A182F22, A182F91, A182F9, 16mo3,15Crmo, da sauransu. | |

| Aikace-aikace | Masana'antar mai; masana'antar jiragen sama da sararin samaniya; masana'antar magunguna; hayakin iskar gas; tashar wutar lantarki; gina jiragen ruwa; sarrafa ruwa, da sauransu. |

| Fa'idodi | kayan da aka shirya, lokacin isarwa da sauri; akwai a cikin kowane girma dabam, an keɓance shi; inganci mai girma |

MATAKAN GIRMA

NUNA BAYANIN KAYAN AIKI

Kayan Aiki & Ginawa:

An yi amfani da na'urar hangen nesa ta ASTM A515 Grade 60, wani abu da aka ƙayyade don aikace-aikacen tasoshin matsin lamba na matsakaici da mafi girma. Yana ba da mafi ƙarancin ƙarfin tauri na 415 MPa (60 ksi) da kuma ingantaccen ƙarfin walda. Don aiki mai mahimmanci, ana iya samar da A516 Grade 60 ko 70.

Daidaita Injin:

Ana yin dukkan saman, musamman fuskokin rufewa da suka taɓa gasket ɗin, har sai sun yi santsi (yawanci 125-250 AARH serrated finish don RF). Ana haƙa ramukan ƙulli kuma a gyara su don daidaita ƙayyadaddun ASME B16.5, wanda ke tabbatar da daidaito da flanges ɗin haɗuwa da kuma hana damuwa a kan ƙulli yayin shigarwa.

Fasalolin Zane:

"Paddle" na tsakiya muhimmin ɓangare ne na abin kallo, yana ba da madauri mai ƙarfi don juyawa da kuma nuna haske a fili. Sau da yawa ana fentin shi da launuka masu haske (misali, rawaya ga gefen spacer, ja ga gefen makaho) bisa ga ƙa'idodin shuka. Ana ƙididdige kauri na sassan makaho da spacer don jure cikakken matsin bututun ruwa da kuma samar da matsi mai kyau na gasket ba tare da lanƙwasa ba.

Aiki:

Na'urar tana juyawa a kan ƙusoshin da ke tsakanin bututun biyu. A matsayin "buɗe", zoben mai sarari yana daidaita da bututun, yana ba da damar kwarara. A matsayin "rufe" ko "makanta", farantin mai ƙarfi yana toshe layin gaba ɗaya, yana samar da wurin keɓewa mai kyau wanda ya fi bawul ɗin rufewa.

Alamar:

An yi masa tambari na dindindin bisa ga buƙatun ASME B16.48, gami da matakin kayan aiki (A515 Gr.60), girma, ajin matsin lamba, da kuma tantance masana'anta.

ALAMOMIN DA RUFEWA

Marufi: Kowace makarar tabarau tana da kariya daban-daban. Ana shafa fuskokin rufewa da injinan da ke hana tsatsa kuma a rufe su da murfi na filastik ko kwali. Sannan a naɗe na'urar da takarda ko filastik na VCI (Vapor Corrosion Inhibitor) don hana tsatsa yayin wucewa. Don manyan girma, ana amfani da akwatunan katako na musamman tare da abin ƙarfafa ciki. Ana iya haɗa ƙananan girma a kan fale-falen tare da kariya daga gefe.

Alama: An haɗa da alamar da ba ta jure yanayi ba, wadda ke bayanin lambar ɓangaren, girma, ajin matsin lamba, kayan aiki, da inda za a je. Akwatin ko fakitin an yi masa alama a sarari da alamomin sarrafawa (misali, "Wannan Gefen Sama," "A Ci gaba da Busarwa").

Jigilar Kaya: Muna amfani da hanyoyin jigilar kaya mafi kyau bisa ga girman oda da gaggawa—daga kwantena na ruwa na yau da kullun don manyan oda zuwa jigilar jiragen sama don buƙatun gaggawa na aiki. Duk takaddun jigilar kaya da ake buƙata (jerin kayan jigilar kaya, takardar kuɗi ta kasuwanci, takardar shaidar asali) an shirya su da kyau don tabbatar da cewa an share kwastam a duk duniya cikin sauƙi.

DUBAWA

Kowace farantin ƙarfe na ASTM A515 Grade 60 tana samun takardar shaidar kayan aiki mai cikakken inganci. Muna gudanar da nazarin sinadarai don tabbatar da cewa sinadaran sun cika buƙatun maki, gami da abubuwan da ke cikin carbon, manganese, phosphorus, sulfur, da silicon. Gwajin halayen injiniya ya haɗa da ƙarfin tauri (mafi ƙarancin 415 MPa), ƙarfin samarwa (mafi ƙarancin 205 MPa), da ma'aunin tsayi bisa ga ƙa'idodin ASTM A370. Don aikace-aikacen ƙananan zafin jiki, ana iya yin gwajin tasirin Charpy V-Notch na zaɓi a yanayin zafi da aka ƙayyade (mafi ƙarancin -29°C) don tabbatar da ƙarfin kayan.

Kowace flange mai makanta ta tabarau tana yin gwajin girma 100% ta amfani da kayan aikin aunawa masu daidaitawa. Mahimman girma da aka duba sun haɗa da: diamita na waje (±1.5mm haƙuri), diamita na da'irar ƙugiya (±0.8mm), diamita na ramin ƙugiya da matsayinsa (±0.5mm), kauri (±0.5mm ga buƙatun ASME B16.48), da kuma lanƙwasa fuska da fuska (cikin 0.2mm a saman rufewa). Ana ba da kulawa ta musamman ga daidaita riƙon madauri da tabbatar da sharewa don daidaitawa mai kyau tsakanin flange na ASME B16.5 na yau da kullun.

Tsarin Samarwa

| 1. Zaɓi ainihin kayan da aka ƙera | 2. Yanke kayan da aka ƙera | 3. Kafin dumamawa |

| 4. Ƙirƙira | 5. Maganin zafi | 6. Injin da ba shi da ƙarfi |

| 7. Hakowa | 8. Kyakkyawan machining | 9. Alamar |

| 10. Dubawa | 11. Shiryawa | 12. Isarwa |

Gabatarwar samfur

Yanayi Mai Amfani Da Yawa: Wannan Hoto Na 8 Na'urar Tsaro ce ta Duniya da ake amfani da ita a duk inda tsarin bututu ke buƙatar keɓancewa mai inganci:

- Matatun Mai da Masana'antu Masu Amfani da Man Fetur: Don ware masu samar da wutar lantarki, ginshiƙai, masu musayar zafi, da famfo yayin gyara ko canza mai.

- Samar da Mai da Iskar Gas/Aika: A kan bututun mai, rijiyoyin ruwa, da kuma kafin a fara amfani da bawuloli na kariya daga matsi (PSVs) don killacewa lafiya yayin gwaji ko gyara.

- Samar da Wutar Lantarki: A cikin layukan tururi, tsarin ruwan abinci, da layukan mai don ware sassan masana'antar don gyara.

- Sarrafa Sinadarai da Magunguna: Don hana gurɓatawa tsakanin rukuni ko yayin tsaftace kayan aiki (CIP/SIP).

- Gyaran Ruwa da Gina Jiragen Ruwa: Don ware famfo, bawuloli, da tankuna a cikin tsarin amfani.

Fa'idodin Kayayyakinmu da Masana'antu:

- Kammala Kera Kayan Cikin Gida: Muna kula da dukkan tsarin tun daga siyan kayan aiki, yankewa, injina, har zuwa kammalawa, tabbatar da inganci da isar da kaya akan lokaci.

- Ƙwarewar Kayan Aiki: Muna ba da jagora kan zaɓin kayan aiki (A515 vs. A516, ƙarfen carbon da bakin ƙarfe) bisa ga takamaiman yanayin aikinku (zafin jiki, matsin lamba, lalata).

- Ƙarfin Keɓancewa: Za mu iya ƙera mayafin tabarau masu kauri marasa daidaito, tare da tsarin ramuka na musamman, ƙirar hannu ta musamman, ko kuma a cikin wasu kayan (bakin ƙarfe, ƙarfe mai ƙarfe) idan an buƙata.

- Tsarin Tsaro na Farko: An ƙera samfuranmu ne da la'akari da amincin mai aiki, tare da faifan madauri masu ƙarfi da daidaito don sauƙin sarrafawa da aminci yayin shigarwa da juyawa.

- Ingantaccen Tsarin Samar da Kayayyaki na Duniya: A matsayinmu na ƙwararren mai fitar da kaya, muna tattarawa da kuma yin rijistar jigilar kaya don cika ƙa'idodin ƙasashen duniya, don tabbatar da cewa kayan aikinku masu mahimmanci ga aminci sun isa wurin a shirye don shigarwa. Muna ba da cikakkun bayanai na fasaha da tallafi don sauƙaƙe haɗakarwa cikin tsarin kulawa da aminci.

Kayan aikin bututun ruwa sune muhimman abubuwa a tsarin bututun, ana amfani da su don haɗawa, sake tura su, karkatar da su, canza girmansu, rufewa ko sarrafa kwararar ruwa. Ana amfani da su sosai a fannoni kamar gini, masana'antu, makamashi da ayyukan birni.

Muhimman Ayyuka:Yana iya yin ayyuka kamar haɗa bututu, canza alkiblar kwarara, rabawa da haɗa kwarara, daidaita diamita na bututu, rufe bututu, sarrafawa da daidaitawa.

Tsarin Aikace-aikace:

- Gina ruwa da magudanar ruwa:Ana amfani da gwiwar hannu na PVC da kuma PPR tris don hanyoyin sadarwa na bututun ruwa.

- Bututun masana'antu:Ana amfani da flanges na bakin karfe da gwiwar hannu na ƙarfe mai ƙarfe don jigilar kayan haɗin sinadarai.

- Sufurin makamashi:Ana amfani da bututun ƙarfe mai ƙarfi a bututun mai da iskar gas.

- HVAC (Dumamawa, Samun Iska, da Kwandishan):Ana amfani da kayan haɗin bututun tagulla don haɗa bututun firiji, kuma ana amfani da haɗin gwiwa masu sassauƙa don rage girgiza.

- Ban ruwa na noma:Masu haɗin sauri suna sauƙaƙa haɗawa da wargaza tsarin ban ruwa na feshin ruwa.