BAYANI

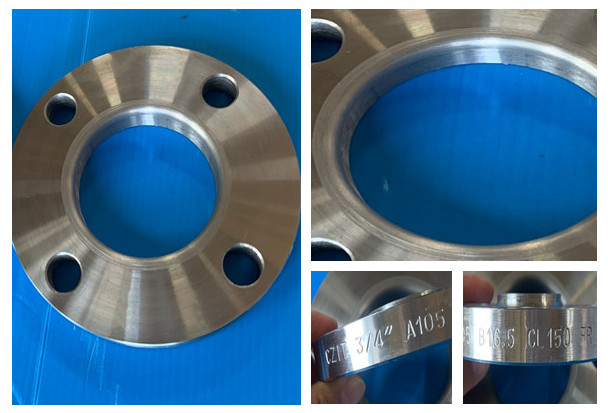

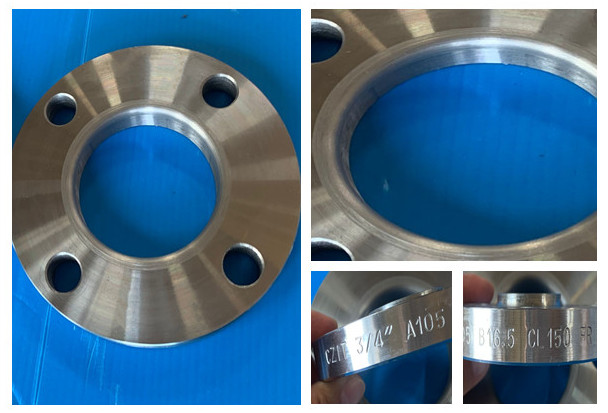

| Sunan Samfuri | Haɗin gwiwa/ƙulli mai laushi |

| Girman | 1/2"-24" |

| Matsi | 150#-2500#,PN0.6-PN400,5K-40K |

| Daidaitacce | ANSI B16.5, EN1092-1, JIS B2220 da dai sauransu. |

| ƙarshen stub | MSS SP 43, ASME B16.9 |

| Kayan Aiki | Bakin karfe:A182F304/304L, A182 F316/316L, A182F321, A182F310S, A182F347H, A182F316Ti, 317/317L, 904L, 1.4301, 1.4307, 1.4401, 1.4571, 1.4541, 254Mo da sauransu. |

| Karfe mai ƙarfi:A105, A350LF2, S235Jr, S275Jr, St37, St45.8, A42CP, A48CP, E24, A515 Gr60, A515 Gr 70 da sauransu. | |

| Bakin ƙarfe mai duplex:UNS31803, SAF2205, UNS32205, UNS31500, UNS32750, UNS32760, 1.4462, 1.4410, 1.4501 da sauransu. | |

| Karfe mai bututun:A694 F42, A694F52, A694 F60, A694 F65, A694 F70, A694 F80 da sauransu. | |

| Haɗin nickel:inconel600, inconel625, inconel690, incoloy800, incoloy 825, incoloy 800H, C22, C-276, Monel400, Alloy20 da sauransu. | |

| Haɗin Cr-Mo:A182F11, A182F5, A182F22, A182F91, A182F9, 16mo3,15Crmo, da sauransu. | |

| Aikace-aikace | Masana'antar mai; masana'antar jiragen sama da sararin samaniya; masana'antar magunguna; hayakin iskar gas; tashar wutar lantarki; gina jiragen ruwa; sarrafa ruwa, da sauransu. |

| Fa'idodi | kayan da aka shirya, lokacin isarwa da sauri; akwai a cikin kowane girma dabam, an keɓance shi; inganci mai girma |

MATAKAN GIRMA

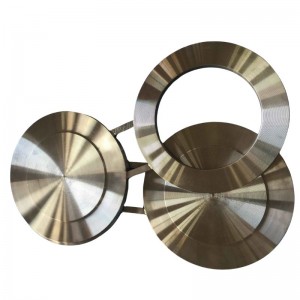

FLANGE NA HADIN Gwiwa

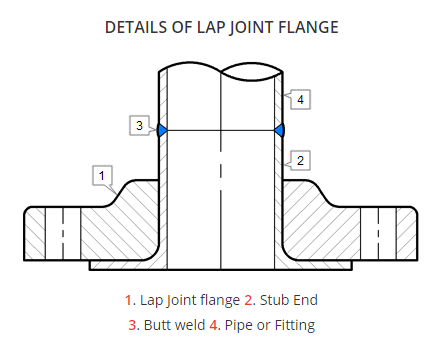

Flange mai haɗin gwiwa yana buƙatar sassan bututu guda biyu a kowane gefen haɗin da aka haɗa, ƙarshen stub da flange mai sassauci. Flange mai sassauci yana dacewa da diamita na waje na ƙarshen stub, wanda aka haɗa shi da duwawu zuwa bututun. Flange mai sassauci ba a haɗa shi da bututun ba, kuma ana iya juya shi, wanda ke da amfani musamman lokacin da ake buƙatar daidaita flange yayin miƙewa.

Haka kuma, tunda flange na baya baya haɗuwa da ruwan aikin, ana iya yin sa da kayan da ba su da juriya ga lalata. Misali, idan aikin yana da lalata kuma yana buƙatar bututun ya kasance da bakin ƙarfe, kamar yadda yake a cikin ASTM A312 TP316L, to ƙarshen stub ɗin kuma dole ne a yi shi da SS 316L; duk da haka, flange na baya ana iya yin shi da ASTM A105 mai rahusa.

Wannan hanyar haɗawa ba ta da ƙarfi kamar flange na wuyan walda amma ta fi scratch, socket weld, da zamewa a kan haɗin gwiwa; duk da haka, ya fi tsada a aiwatar da shi, saboda yana buƙatar cikakken walda na butt kuma yana buƙatar sassa biyu.

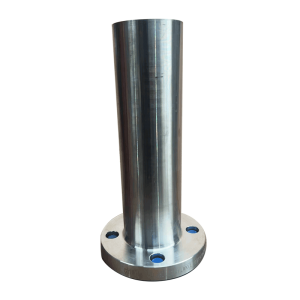

ƘARSHEN STUB

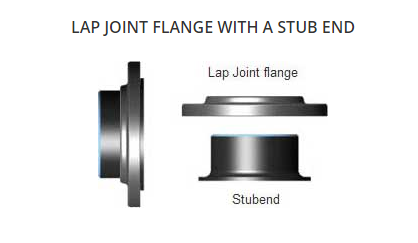

Za a yi amfani da ƙarshen Stub End tare da flange na Lap Joint, a matsayin flange na baya.

Ana amfani da wannan haɗin flange, a cikin aikace-aikacen ƙarancin matsin lamba da waɗanda ba su da mahimmanci, kuma hanya ce mai arha ta flange.

Misali, a tsarin bututun bakin karfe, ana iya amfani da flange na ƙarfen carbon, saboda ba sa hulɗa da samfurin da ke cikin bututun.

Ana samun ƙarshen bututu a kusan dukkan diamita na bututu. Girma da juriyar girma an ayyana su a cikin ma'aunin ASME B.16.9. An ayyana ƙarshen bututun mai jure tsatsa mai sauƙi (fitarwa) a cikin MSS SP43.

AMFANI DA FLANGE NA HADIN Gwiwa NA LAP

- 'Yancin juyawa a kusa da bututun yana sauƙaƙa layin ramukan ƙusoshin flange masu adawa da juna.

- Rashin haɗuwa da ruwan da ke cikin bututun sau da yawa yana ba da damar amfani da flanges na ƙarfe mai araha waɗanda ke da bututun da ke jure tsatsa.

- A cikin tsarin da ke lalacewa ko lalacewa da sauri, ana iya adana flanges ɗin don sake amfani da su.

NUNA BAYANIN KAYAN AIKI

1. Fuska

Fuska mai faɗi, Radius shine mafi mahimmanci

2. Da cibiya ko ba tare da cibiya ba

3. Kammala fuska

Ana auna ƙarshen da ke kan fuskar flange a matsayin Matsakaicin Tsayin Lissafi (AARH). Ana ƙayyade ƙarshen ta hanyar ma'aunin da aka yi amfani da shi. Misali, ANSI B16.5 yana ƙayyade ƙarewar fuska a cikin kewayon 125AARH-500AARH (3.2Ra zuwa 12.5Ra). Ana samun sauran ƙarewar akan buƙata, misali 1.6 Ra max, 1.6/3.2 Ra, 3.2/6.3Ra ko 6.3/12.5Ra. Zangon 3.2/6.3Ra shine mafi yawan lokuta.

ALAMOMIN DA RUFEWA

• Kowace Layer tana amfani da fim ɗin filastik don kare saman

• Ga dukkan bakin karfe, ana sanya su a cikin akwatin plywood. Don girman girman carbon flange, ana sanya su a cikin pallet na plywood. Ko kuma ana iya yin su musamman.

• Ana iya yin alamar jigilar kaya akan buƙata

• Ana iya sassaka ko buga alamun da ke kan samfura. Ana karɓar OEM.

DUBAWA

• Gwajin UT

• Gwajin PT

• Gwajin MT

• Gwajin Girma

Kafin isarwa, ƙungiyar QC ɗinmu za ta shirya gwajin NDT da duba girma. Hakanan za ta karɓi TPI (dubawa ta ɓangare na uku).

Tsarin Samarwa

| 1. Zaɓi ainihin kayan da aka ƙera | 2. Yanke kayan da aka ƙera | 3. Kafin dumamawa |

| 4. Ƙirƙira | 5. Maganin zafi | 6. Injin da ba shi da ƙarfi |

| 7. Hakowa | 8. Kyakkyawan machining | 9. Alamar |

| 10. Dubawa | 11. Shiryawa | 12. Isarwa |

Flange mai haɗin gwiwa yana buƙatar sassan bututu guda biyu a kowane gefen haɗin da aka haɗa, ƙarshen stub da flange mai sassauci. Flange mai sassauci yana dacewa da diamita na waje na ƙarshen stub, wanda aka haɗa shi da duwawu zuwa bututun. Flange mai sassauci ba a haɗa shi da bututun ba, kuma ana iya juya shi, wanda ke da amfani musamman lokacin da ake buƙatar daidaita flange yayin miƙewa.

Haka kuma, tunda flange na baya baya haɗuwa da ruwan aikin, ana iya yin sa da kayan da ba su da juriya ga lalata. Misali, idan aikin yana da lalata kuma yana buƙatar bututun ya kasance da bakin ƙarfe, kamar yadda yake a cikin ASTM A312 TP316L, to ƙarshen stub ɗin kuma dole ne a yi shi da SS 316L; duk da haka, flange na baya ana iya yin shi da ASTM A105 mai rahusa.

Wannan hanyar haɗawa ba ta da ƙarfi kamar flange na wuyan walda amma ta fi scratch, socket weld, da zamewa a kan haɗin gwiwa; duk da haka, ya fi tsada a aiwatar da shi, saboda yana buƙatar cikakken walda na butt kuma yana buƙatar sassa biyu.

Za a yi amfani da ƙarshen Stub End tare da flange na Lap Joint, a matsayin flange na baya.

Ana amfani da wannan haɗin flange, a cikin aikace-aikacen ƙarancin matsin lamba da waɗanda ba su da mahimmanci, kuma hanya ce mai arha ta flange.

Misali, a tsarin bututun bakin karfe, ana iya amfani da flange na ƙarfen carbon, saboda ba sa hulɗa da samfurin da ke cikin bututun.

Ana samun ƙarshen bututu a kusan dukkan diamita na bututu. Girma da juriyar girma an ayyana su a cikin ma'aunin ASME B.16.9. An ayyana ƙarshen bututun mai jure tsatsa mai sauƙi (fitarwa) a cikin MSS SP43.

- 'Yancin juyawa a kusa da bututun yana sauƙaƙa layin ramukan ƙusoshin flange masu adawa da juna.

- Rashin haɗuwa da ruwan da ke cikin bututun sau da yawa yana ba da damar amfani da flanges na ƙarfe mai araha waɗanda ke da bututun da ke jure tsatsa.

- A cikin tsarin da ke lalacewa ko lalacewa da sauri, ana iya adana flanges ɗin don sake amfani da su.

Nunin cikakken bayani game da samfuran

1. Fuska

Fuska mai faɗi, Radius shine mafi mahimmanci

2. Da cibiya ko ba tare da cibiya ba

3. Kammala fuska

Ana auna ƙarshen da ke kan fuskar flange a matsayin Matsakaicin Tsayin Lissafi (AARH). Ana ƙayyade ƙarshen ta hanyar ma'aunin da aka yi amfani da shi. Misali, ANSI B16.5 yana ƙayyade ƙarewar fuska a cikin kewayon 125AARH-500AARH (3.2Ra zuwa 12.5Ra). Ana samun sauran ƙarewar akan buƙata, misali 1.6 Ra max, 1.6/3.2 Ra, 3.2/6.3Ra ko 6.3/12.5Ra. Zangon 3.2/6.3Ra shine mafi yawan lokuta.

Alamar da marufi

• Kowace Layer tana amfani da fim ɗin filastik don kare saman

• Ga dukkan bakin karfe, ana sanya su a cikin akwatin plywood. Don girman girman carbon flange, ana sanya su a cikin pallet na plywood. Ko kuma ana iya yin su musamman.

• Ana iya yin alamar jigilar kaya akan buƙata

• Ana iya sassaka ko buga alamun da ke kan samfura. Ana karɓar OEM.

Dubawa

• Gwajin UT

• Gwajin PT

• Gwajin MT

• Gwajin Girma

Kafin isarwa, ƙungiyar QC ɗinmu za ta shirya gwajin NDT da duba girma. Hakanan za ta karɓi TPI (dubawa ta ɓangare na uku).

Tsarin samarwa

| 1. Zaɓi ainihin kayan da aka ƙera | 2. Yanke kayan da aka ƙera | 3. Kafin dumamawa |

| 4. Ƙirƙira | 5. Maganin zafi | 6. Injin da ba shi da ƙarfi |

| 7. Hakowa | 8. Kyakkyawan machining | 9. Alamar |

| 10. Dubawa | 11. Shiryawa | 12. Isarwa |

Kayan aikin bututun ruwa sune muhimman abubuwa a tsarin bututun, ana amfani da su don haɗawa, sake tura su, karkatar da su, canza girmansu, rufewa ko sarrafa kwararar ruwa. Ana amfani da su sosai a fannoni kamar gini, masana'antu, makamashi da ayyukan birni.

Muhimman Ayyuka:Yana iya yin ayyuka kamar haɗa bututu, canza alkiblar kwarara, rabawa da haɗa kwarara, daidaita diamita na bututu, rufe bututu, sarrafawa da daidaitawa.

Tsarin Aikace-aikace:

- Gina ruwa da magudanar ruwa:Ana amfani da gwiwar hannu na PVC da kuma PPR tris don hanyoyin sadarwa na bututun ruwa.

- Bututun masana'antu:Ana amfani da flanges na bakin karfe da gwiwar hannu na ƙarfe mai ƙarfe don jigilar kayan haɗin sinadarai.

- Sufurin makamashi:Ana amfani da bututun ƙarfe mai ƙarfi a bututun mai da iskar gas.

- HVAC (Dumamawa, Samun Iska, da Kwandishan):Ana amfani da kayan haɗin bututun tagulla don haɗa bututun firiji, kuma ana amfani da haɗin gwiwa masu sassauƙa don rage girgiza.

- Ban ruwa na noma:Masu haɗin sauri suna sauƙaƙa haɗawa da wargaza tsarin ban ruwa na feshin ruwa.

-

Ansi B16.5 A105 Baƙin Carbon Karfe Zamewa akan Flange

-

Musamman Ba Standard Tube Sheet Flange Tabo ...

-

ASME b16.48 Siffar ƙarfe mai kama da carbon 8 ...

-

Bakin Karfe 304 304L 316 316L ASTM da aka ƙera t...

-

Dogon Wuya Wuya Flange Standard Matsi LWN Ga ...

-

ANSI B16.5 Ƙirƙirar Bakin Karfe Soket Weld F...