BAYANI

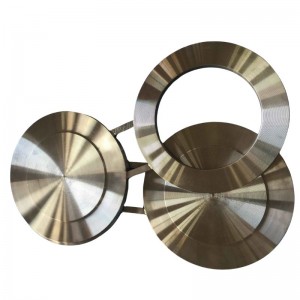

| Sunan samfur | Haɗin gwiwar cinya/Sauke flange |

| Girman | 1/2" - 24" |

| Matsi | 150#-2500#,PN0.6-PN400,5K-40K |

| Daidaitawa | ANSI B16.5, EN1092-1, JIS B2220 da dai sauransu. |

| Ƙarshen kututture | MSS SP 43, ASME B16.9 |

| Kayan abu | Bakin Karfe:A182F304/304L, A182 F316/316L, A182F321, A182F310S, A182F347H, A182F316Ti, 317/317L, 904L, 1.4301, 1,4307 1.4571,1.4541, 254Mo da dai sauransu. |

| Karfe Karfe:A105, A350LF2, S235Jr, S275Jr, St37, St45.8, A42CP, A48CP, E24 , A515 Gr60, A515 Gr 70 da dai sauransu. | |

| Duplex bakin karfe:UNS31803, SAF2205, UNS32205, UNS31500, UNS32750 , UNS32760, 1.4462,1.4410,1.4501 da dai sauransu. | |

| Bututun karfe:A694 F42, A694F52, A694 F60, A694 F65, A694 F70, A694 F80 da dai sauransu. | |

| Alloy na nickel:inconel600, inconel625, inconel690, incoloy800, incoloy 825, incoloy 800H, C22, C-276, Monel400, Alloy20 da dai sauransu. | |

| Cr-Mo alloy:A182F11, A182F5, A182F22, A182F91, A182F9, 16mo3,15Crmo, da dai sauransu. | |

| Aikace-aikace | Petrochemical masana'antu, sufurin jiragen sama da Aerospace masana'antu, Pharmaceutical masana'antu, iskar gas shaye, wutar lantarki, jirgin gini, ruwa jiyya, da dai sauransu. |

| Amfani | shirye stock, sauri bayarwa lokaci; samuwa a duk masu girma dabam, musamman; high quality |

MATSAYIN GIRMA

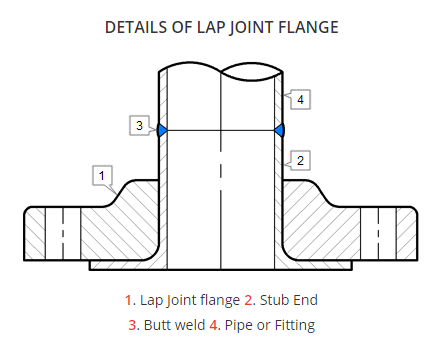

RANAR HADA KAN LAP

Flange-haɗin gwiwa yana buƙatar abubuwan haɗin bututu guda biyu don kowane gefen haɗin flanged, ƙarshen stub da saƙon goyan baya. Flange ɗin mara baya ya yi daidai da diamita na waje na ƙarshen stub, wanda aka welded zuwa bututu. Ba a haɗa flange na baya zuwa bututu ba, kuma ana iya jujjuya shi, wanda ke da amfani musamman lokacin da ya zama dole don daidaita flanges yayin haɓakawa.

Hakanan, kamar yadda flange na goyan baya baya haɗuwa da ruwan tsari, ana iya yin shi da ƙaramin abu mai jurewa. Misali, idan tsarin ya lalace kuma yana buƙatar bututun ya zama na bakin karfe, kamar yadda yake a cikin ASTM A312 TP316L, to dole ne a yi ƙarshen stub da SS 316L; Koyaya, ana iya yin flange na goyan bayan ASTM A105 mai rahusa.

Wannan hanyar haɗin gwiwa ba ta da ƙarfi kamar flange wuyan walda amma ya fi screwed, soket weld, da zamewa akan haɗin gwiwa; duk da haka, ya fi tsada don aiwatarwa, saboda yana buƙatar cikakken shigar butt weld kuma yana buƙatar abubuwa biyu.

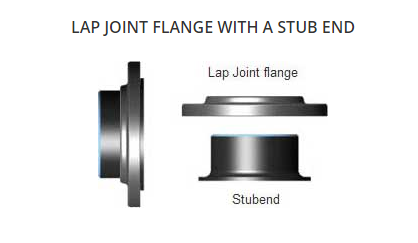

KARSHEN KUNGIYA

Za a yi amfani da Ƙarshen Ƙarshen Koyaushe tare da Haɗin Haɗin gwiwa na Lap, azaman flange mai goyan baya.

Ana amfani da wannan haɗin flange, a cikin ƙananan matsi da aikace-aikace marasa mahimmanci, kuma hanya ce mai arha ta flanging.

A cikin tsarin bututu na bakin karfe, alal misali, ana iya amfani da flange na ƙarfe na carbon, saboda ba su haɗu da samfurin a cikin bututu ba.

Stub Ends suna samuwa a kusan duk diamita na bututu. An bayyana ma'auni da juriya mai girma a cikin ma'aunin ASME B.16.9. Ƙarshen Stub Ƙarshen (kayan ɗaki) mai ɗaukar nauyi mai sauƙi an bayyana shi a cikin MSS SP43.

AMFANIN KARFIN HAɗin GINDI

- 'Yancin jujjuyawa a kusa da bututu yana sauƙaƙe jeri na ramukan kusoshi na flange.

- Rashin tuntuɓar ruwa a cikin bututu sau da yawa yana ba da izinin amfani da flanges na ƙarfe na carbon mara tsada tare da bututu mai jure lalata.

- A cikin tsarin da ke lalacewa ko lalacewa da sauri, ana iya ceton filaye don sake amfani da su.

KYAUTATA BAYANIN BAYANIN

1. Fuska

lebur fuska, Radius shine mafi mahimmanci

2. Tare da cibiya ko babu cibiya

3.Garewar fuska

Ƙarshen a kan fuskar flange ana auna shi azaman Matsakaicin Matsakaici Roughness Height (AARH). Ƙarshen yana ƙaddara ta daidaitattun da aka yi amfani da shi. Misali, ANSI B16.5 yana ƙayyade ƙarewar fuska tsakanin kewayon 125AARH-500AARH (3.2Ra zuwa 12.5Ra). Ana samun sauran ƙare akan buƙata, misali 1.6 Ra max, 1.6/3.2 Ra, 3.2/6.3Ra ko 6.3/12.5Ra. Matsakaicin 3.2/6.3Ra ya fi kowa.

MARKING DA KYAUTA

• Kowane Layer yana amfani da fim ɗin filastik don kare farfajiya

• Don duk bakin karfe an cika su da akwati plywood. Don girman girman carbon flange an cika shi da pallet plywood. Ko za a iya keɓance shiryawa.

• Alamar jigilar kaya na iya yin akan buƙata

Ana iya sassaƙawa ko buga alamar samfura. OEM an karɓa.

BINCIKE

• Gwajin UT

• Gwajin PT

• Gwajin MT

• Gwajin girma

Kafin bayarwa, ƙungiyarmu ta QC za ta shirya gwajin gwajin NDT da duba girma. Hakanan karɓar TPI (duba na ɓangare na uku).

HANYAR KIRKI

| 1. Zabi Gaske albarkatun kasa | 2. Yanke albarkatun kasa | 3. Kafin dumama |

| 4. Yin jabu | 5. Maganin zafi | 6. Rough Machining |

| 7. Hakowa | 8. Kyakkyawar maching | 9. Alama |

| 10. Dubawa | 11. Shiryawa | 12. Bayarwa |

Flange-haɗin gwiwa yana buƙatar abubuwan haɗin bututu guda biyu don kowane gefen haɗin flanged, ƙarshen stub da saƙon goyan baya. Flange ɗin mara baya ya yi daidai da diamita na waje na ƙarshen stub, wanda aka welded zuwa bututu. Ba a haɗa flange na baya zuwa bututu ba, kuma ana iya jujjuya shi, wanda ke da amfani musamman lokacin da ya zama dole don daidaita flanges yayin haɓakawa.

Hakanan, kamar yadda flange na goyan baya baya haɗuwa da ruwan tsari, ana iya yin shi da ƙaramin abu mai jurewa. Misali, idan tsarin ya lalace kuma yana buƙatar bututun ya zama na bakin karfe, kamar yadda yake a cikin ASTM A312 TP316L, to dole ne a yi ƙarshen stub da SS 316L; Koyaya, ana iya yin flange na goyan bayan ASTM A105 mai rahusa.

Wannan hanyar haɗin gwiwa ba ta da ƙarfi kamar flange wuyan walda amma ya fi screwed, soket weld, da zamewa akan haɗin gwiwa; duk da haka, ya fi tsada don aiwatarwa, saboda yana buƙatar cikakken shigar butt weld kuma yana buƙatar abubuwa biyu.

Za a yi amfani da Ƙarshen Ƙarshen Koyaushe tare da Haɗin Haɗin gwiwa na Lap, azaman flange mai goyan baya.

Ana amfani da wannan haɗin flange, a cikin ƙananan matsi da aikace-aikace marasa mahimmanci, kuma hanya ce mai arha ta flanging.

A cikin tsarin bututu na bakin karfe, alal misali, ana iya amfani da flange na ƙarfe na carbon, saboda ba su haɗu da samfurin a cikin bututu ba.

Stub Ends suna samuwa a kusan duk diamita na bututu. An bayyana ma'auni da juriya mai girma a cikin ma'aunin ASME B.16.9. Ƙarshen Stub Ƙarshen (kayan ɗaki) mai ɗaukar nauyi mai sauƙi an bayyana shi a cikin MSS SP43.

- 'Yancin jujjuyawa a kusa da bututu yana sauƙaƙe jeri na ramukan kusoshi na flange.

- Rashin tuntuɓar ruwa a cikin bututu sau da yawa yana ba da izinin amfani da flanges na ƙarfe na carbon mara tsada tare da bututu mai jure lalata.

- A cikin tsarin da ke lalacewa ko lalacewa da sauri, ana iya ceton filaye don sake amfani da su.

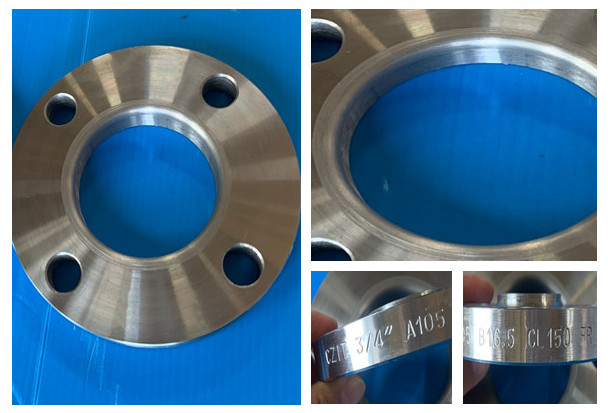

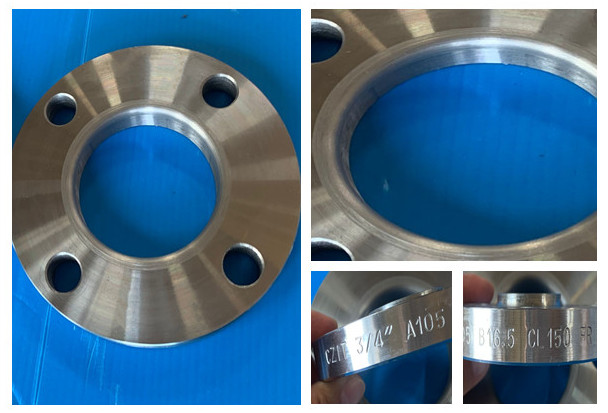

Samfuran cikakkun bayanai sun nuna

1. Fuska

lebur fuska, Radius shine mafi mahimmanci

2. Tare da cibiya ko babu cibiya

3.Garewar fuska

Ƙarshen a kan fuskar flange ana auna shi azaman Matsakaicin Matsakaici Roughness Height (AARH). Ƙarshen yana ƙaddara ta daidaitattun da aka yi amfani da shi. Misali, ANSI B16.5 yana ƙayyade ƙarewar fuska tsakanin kewayon 125AARH-500AARH (3.2Ra zuwa 12.5Ra). Ana samun sauran ƙare akan buƙata, misali 1.6 Ra max, 1.6/3.2 Ra, 3.2/6.3Ra ko 6.3/12.5Ra. Matsakaicin 3.2/6.3Ra ya fi kowa.

Alama da shiryawa

• Kowane Layer yana amfani da fim ɗin filastik don kare farfajiya

• Don duk bakin karfe an cika su da akwati plywood. Don girman girman carbon flange an cika shi da pallet plywood. Ko za a iya keɓance shiryawa.

• Alamar jigilar kaya na iya yin akan buƙata

Ana iya sassaƙawa ko buga alamar samfura. OEM an karɓa.

Dubawa

• Gwajin UT

• Gwajin PT

• Gwajin MT

• Gwajin girma

Kafin bayarwa, ƙungiyarmu ta QC za ta shirya gwajin gwajin NDT da duba girma. Hakanan karɓar TPI (duba na ɓangare na uku).

Tsarin samarwa

| 1. Zabi Gaske albarkatun kasa | 2. Yanke albarkatun kasa | 3. Kafin dumama |

| 4. Yin jabu | 5. Maganin zafi | 6. Rough Machining |

| 7. Hakowa | 8. Kyakkyawar maching | 9. Alama |

| 10. Dubawa | 11. Shiryawa | 12. Bayarwa |

-

ASTM A182 F51 F53 BL ANSI B16.5 Bakin Karfe ...

-

A105 150lb Dn150 carbon karfe waldi zamewa a kan f ...

-

Manufacturer ƙwararrun ƙirƙira babban matsin lamba ...

-

filafili blank spacer A515 gr 60 adadi 8 spectac ...

-

ASME b16.48 Factory Sale carbon karfe adadi 8 ...

-

carbon karfe A105 ƙirƙira makafi BL flange